289 build

- Roger King

- Posts: 4396

- Joined: Mon Mar 19, 2007 10:29 pm

- Location: St Ives, Cambs

Re: 289 build

Yes, milling reliefs in the piston crowns would require a rebalance. I've not seen any SBF performance motor without them, but remember this would affect your CR as well. What ratio rockers are you using?

- amulheirn

- T289R Committee

- Posts: 1207

- Joined: Mon May 13, 2013 2:30 pm

- Location: Surrey/Hampshire

- Contact:

Re: 289 build

Hi Roger - I'm using 1.6 ratio, which I think is standard.

I think I'll save the cam for some future engine build or maybe sell it if I find someone else who needs a roller cam. I looked at Comp's other roller cams and they're all over 0.50" lift, so I couldn't really see another option. If I was doing this again with the knowledge I have now, I'd probably have bought a non-roller block I think.

Come to think of it, is there a way to convert a roller block to a non-roller one? Is it just the lifter bores that are higher and the two threaded holes for the spider in the lifter valley? (That said, even if this were possible, I need to get on with building the car really!).

Andrew

I think I'll save the cam for some future engine build or maybe sell it if I find someone else who needs a roller cam. I looked at Comp's other roller cams and they're all over 0.50" lift, so I couldn't really see another option. If I was doing this again with the knowledge I have now, I'd probably have bought a non-roller block I think.

Come to think of it, is there a way to convert a roller block to a non-roller one? Is it just the lifter bores that are higher and the two threaded holes for the spider in the lifter valley? (That said, even if this were possible, I need to get on with building the car really!).

Andrew

- amulheirn

- T289R Committee

- Posts: 1207

- Joined: Mon May 13, 2013 2:30 pm

- Location: Surrey/Hampshire

- Contact:

Re: 289 build

Fitted a Modern DriveLine hydraulic clutch slave cylinder to the bellhousing tonight. Here's what is in the kit:

Modern Driveline hydraulic clutch slave cylinder kit contents by Andrew Mulheirn, on Flickr

Modern Driveline hydraulic clutch slave cylinder kit contents by Andrew Mulheirn, on Flickr

First, measure up the centreline of the bracket and the centreline of the clutch arm aperture:

Move the bracket to the top and mark the holes to be drilled:

Holes drilled and bracket fitted:

Slave itself, with pushrod removed:

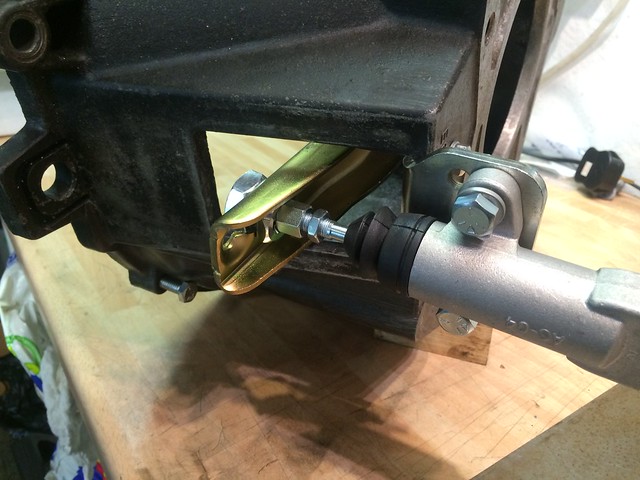

How the pushrod attaches to the clutch arm - a special concave nut is supplied that fits into the bigger hole in the clutch arm (next to where the cable would be in a cable-operated system):

Same again, this time assembled - small convex nut on pushrod sits in the bigger concave nut on the arm:

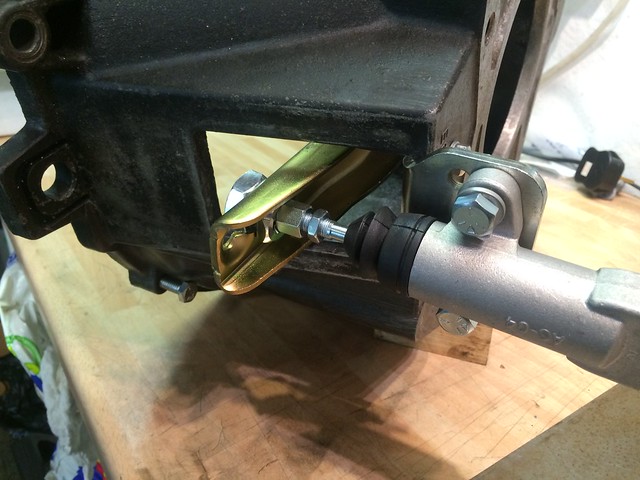

Cylinder attached to the bellhousing:

View from the engine side:

Correct way to attach the thrust-bearing to the clutch arm (unlubricated at the point this photo was taken):

Modern Driveline hydraulic clutch slave cylinder kit contents by Andrew Mulheirn, on Flickr

Modern Driveline hydraulic clutch slave cylinder kit contents by Andrew Mulheirn, on FlickrFirst, measure up the centreline of the bracket and the centreline of the clutch arm aperture:

Move the bracket to the top and mark the holes to be drilled:

Holes drilled and bracket fitted:

Slave itself, with pushrod removed:

How the pushrod attaches to the clutch arm - a special concave nut is supplied that fits into the bigger hole in the clutch arm (next to where the cable would be in a cable-operated system):

Same again, this time assembled - small convex nut on pushrod sits in the bigger concave nut on the arm:

Cylinder attached to the bellhousing:

View from the engine side:

Correct way to attach the thrust-bearing to the clutch arm (unlubricated at the point this photo was taken):

-

Paul Blore

- Posts: 2077

- Joined: Sat Nov 15, 2008 8:20 pm

- Location: Leicestershire, UK

- Contact:

Re: 289 build

That looks like a nice kit Andy and well documented.

Paul

Paul

- amulheirn

- T289R Committee

- Posts: 1207

- Joined: Mon May 13, 2013 2:30 pm

- Location: Surrey/Hampshire

- Contact:

Re: 289 build

Thanks Paul! I might write it up a bit more for the mag. Roger put me on to it. Because it mounts aft of the bellhousing, there aren't any clearance issues in the transmission tunnel, which is nice.

What I'm not sure about is:

1. What the threads are on it (not stated in the manual, so I emailed the manufacturer to ask)

2. How it will work with the Hawk-supplied master cylinder. Not sure if I will need a master with a different bore or stroke - and since I don't yet have the master cylinder, I can't try it out.

Cheers,

Andy

What I'm not sure about is:

1. What the threads are on it (not stated in the manual, so I emailed the manufacturer to ask)

2. How it will work with the Hawk-supplied master cylinder. Not sure if I will need a master with a different bore or stroke - and since I don't yet have the master cylinder, I can't try it out.

Cheers,

Andy

- StewbieC

- T289R Committee

- Posts: 1360

- Joined: Mon Oct 13, 2008 12:50 pm

- Location: out in the sticks, Shropshire

Re: 289 build

I hope you are right with the clearance.

________________________________________________

Stu

Hawk 289, 66 Mustang Fastback with a 289 maximum smiles per mile..

Stu

Hawk 289, 66 Mustang Fastback with a 289 maximum smiles per mile..

- Roger King

- Posts: 4396

- Joined: Mon Mar 19, 2007 10:29 pm

- Location: St Ives, Cambs

Re: 289 build

I did? I have to admit to no knowledge of 'puller' slave cylinders. I would certainly recommend MD, but for my Hawk's T5 clutch actuation I used Gerry's arrangement with the repositioned fulcrum and the bog standard Girling cylinder.amulheirn wrote:Roger put me on to it.

Roger

Re: 289 build

This is a "pusher" slave cylinder. I also have one, but mounted to a bracket that is fastened to the T5. Works a dream!

- Roger King

- Posts: 4396

- Joined: Mon Mar 19, 2007 10:29 pm

- Location: St Ives, Cambs

Re: 289 build

Yes, I see now that it is. Out of interest, why choose this over Gerry's offering?Karl wrote:This is a "pusher" slave cylinder. I also have one, but mounted to a bracket that is fastened to the T5. Works a dream!

Re: 289 build

Well, my reason was:

The fork arrangement stays the same as with the cable operated clutch, the ball position stays on the RH side and the push force is lower, because the fork resst on the right side and you push on the far left side. The cylinder is bolted with the bracket to the T 5, so no drilling and enough clearance.

The fork arrangement stays the same as with the cable operated clutch, the ball position stays on the RH side and the push force is lower, because the fork resst on the right side and you push on the far left side. The cylinder is bolted with the bracket to the T 5, so no drilling and enough clearance.